Table of Contents

TL;DR Summary

Importing furniture from China remains one of the most reliable and cost-effective sourcing strategies in 2025.

This comprehensive guide by Adam Gilbourne, Founder of Easy Imex, explains how to build a successful import process — from identifying the right suppliers and manufacturing regions to managing pricing, compliance, and logistics for the UK, US, and Australian markets.

It covers:

- How China’s furniture industry remains the global leader in production and supply chain efficiency.

- Key factors to consider before importing — including business models, MOQs, and legal requirements.

- A full step-by-step guide covering supplier sourcing, cost calculation, sampling, contracts, and shipping.

- The most common challenges importers face (quality, communication, compliance, freight volatility) — and how to prevent them.

- Why partnering with a local buying office like Easy Imex provides long-term reliability, transparency, and quality control.

Whether you’re a new importer or an established retailer scaling globally, this guide outlines everything you need to import furniture from China confidently and profitably.

If you or your business are, or are planning to import furniture from China, then this guide is absolutely worth a read.

This guide is written by Adam Gilbourne, the founder and CEO of Easy Imex. Adam visited China in 2004 and has ever since been working with businesses from all over the world, importing goods from China, particularly furniture.

Easy Imex, founded in 2004, has helped over 3,000 importers source furniture directly from verified factories in China.

In this guide, Adam shares some remarkably useful insights from his ‘on the ground’ experience of what it takes to import furniture from China and get it right!

Is Importing Furniture from China Still Profitable in 2025?

Despite the Importing from China furniture guide retaining relevance in today’s business climate, there are a few crucial updates we would like to mention to furniture importers in the post-COVID era.

1. Why Import Furniture from China? (2025 Update)

China remains the world’s leading furniture manufacturer, offering unmatched supply chain integration, large-scale production, and cost efficiency.

Generally speaking, China still has a lot of advantages when it comes to furniture production, supply chains being one of them. Let’s take an example of a simple flat-packed TV cabinet with chrome-plated hairpin legs.

Unlike textiles, the supply chain is much more complex. There is the manufacturing of the particle board/MDF, the production of the paper/melamine/vinyl to cover it with. The manufacturing of all the screws and fittings, plus metal manufacture for the metal legs, and the coating factory to chrome the legs are also inclusive.

Apart from this, China still retains kings-spot when mass production at low costs comes into consideration. Later in this guide, we will also give examples of Chinese factory owners, who moved from their outdoor rattan garden furniture to Vietnam, only to close it down and move back to China. While they could achieve a lower wage cost than in China, they ended up having major productivity issues.

In 2025, the main furniture clusters in Foshan, Dongguan, and Zhejiang continue to lead global exports, supported by mature supply chains and strong compliance standards.

2. What to Consider Before Importing Furniture from China

Before starting the process, importers should understand whether their business model and operational scale are aligned with the way Chinese factories operate. Furniture manufacturing in China is built around mass production and regular repeat orders, rather than one-off or small-batch manufacturing.

A) Which Business Models Work Best for Importing Furniture from China?

For any business looking to import furniture from China, your business model as an ‘importer’ must align with ‘China.’ What China does well is mass production.

Setting mass production up, of course, require a lot of time and expertise, as we have also analyzed in this guide. As such, this time and effort are worth it unless your business model needs a regular supply of mass-produced goods.

Successful vs. unsuccessful business model

To give an example of that, see below an explanation of two different business models, which one would work and which one wouldn’t when it comes to importing furniture from China.

Business Model One – Not suitable to be a China Furniture importer!

A business with just a shop as its sole outlet to sell furniture, boutique pieces of unique furniture, will almost always buy in minimal quantities from its suppliers.

Consequently, a business like this should NOT look to buy from China. This business would never import regular containers from factories. They have a small market and low volume, which is not suitable to import furniture from China, especially for a product like furniture.

Business Model Two – A business that sells high volumes

A business that sells either online/offline has warehouse capabilities to intake container loads of stock. They also have a sales channel, which means they can turn over their inventories at a quick rate, and as such, will need to keep re-ordering the same pieces of furniture.

A business like this should be buying from China since they have a large market and high volume, which is totally suitable to import furniture from China.

China is ideal for importers who sell at scale — online or offline — and can reorder regularly. Smaller boutique retailers and design studios often struggle to meet factory minimum order quantities (MOQs) or justify container shipments. For these businesses, working through a sourcing agent or buying office that consolidates orders can still make importing feasible without committing to high volumes.

Should You Import Directly or Use an Agent / Buying Office in China?

Once you have decided to import furniture from China, the next line of action is deciding how to import such pieces of furniture from China.

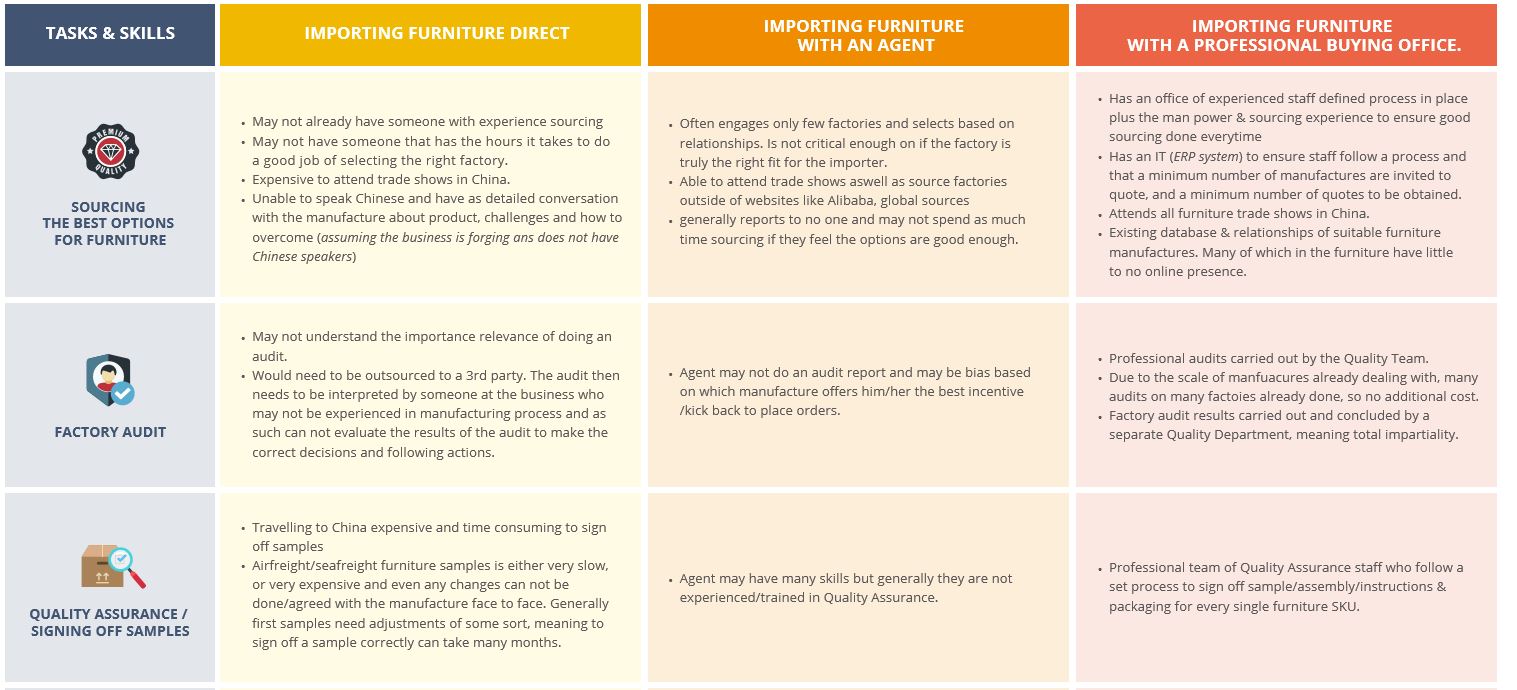

You or your business can either import furniture directly from China, or otherwise, make use of an agent, or even a buying office.

There are, of course, ‘pros’ and ‘cons’ to all of these. For example, if you were to import direct ‘theoretically,’ you would get the best price. However, what if an agent was able to source a better factory and get a better price?

If you’re importing directly again, while you may ‘theoretically’ get the best unit price on your furniture, you should know that a professional furniture-buying office will help you a great deal in growing your business faster. This, they will do by taking away the headaches that may arise from new furniture ranges, assemblage, instructions, packaging (especially if you’re an eCommerce seller of furniture).

Of course, by default, making use of an agent or a buying-office allows such an agent or office to add a margin for themselves, which may consequently ‘take away value’ from your business. However, a good agent or buying-office would, in the long run, actually ‘add value’ in many areas, meaning your business could be much better off by using one.

Summary Comparison: Importing Direct vs Using an Agent or Buying Office

Option | Pros | Cons | Best for |

Direct Import | Lowest possible unit cost | Requires in-depth knowledge, high risk, language barriers, and time-consuming QC | Experienced importers with in-house logistics & quality control |

Sourcing Agent | Access to multiple suppliers, easier communication, reduced workload | Adds a small commission, quality may depend on agent competence | Small to mid-sized importers starting in China |

Buying Office | End-to-end management: sourcing, QC, shipping, and compliance handled locally | Slightly higher service cost but higher efficiency | Growing importers or brands managing continuous container shipments |

For any small to medium-sized importer, one key question to ask is why large businesses and established furniture brands eventually own a furniture-buying office in China? We will attempt to answer that in the next section.

Outsourcing to a furniture-buying office/sourcing company

When you’re importing furniture from China, generally, there are three ways to conduct your transactions/businesses. Either the importer (you) contacts a supplier directly (who may or may not be whom you think they are), make use of a ‘sourcing agent,’ or a Furniture-Buying Office, a sourcing company.

Easy Imex operates as a professional furniture buying office based in China, supporting importers worldwide with sourcing, quality control, logistics coordination, and on-the-ground supplier management. With over two decades of experience, the company provides end-to-end oversight to help importers avoid costly mistakes and maintain consistent product standards.

Of course, different businesses all have different people with diverse experiences and skillsets. And the same applies to source-agents too. Some are highly competent agents; some are incompetent, immoral (the worse type). There are also buying-offices that are amazing, as well as entirely awful buying-offices, with no process and professional staff.

As such, it impossible to come to any firm conclusion about what’s going to be best for your business. This is something that only you, the importer, can decide.

However, I possess over a decade’s experience in China, working with hundreds of importers, essentially starting as a sourcing agent myself, and building easyimex.com to become the professional Furniture Buying office it is today. After all these, and also saving several importers from the perils of working with terrible agents, I am going to draw a table based on ‘typical scenarios’.

Again, this table is not conclusive. It does not mean an import business can’t successfully import from China. Likewise, it does not mean all agents are bad!

However, I happen to be one who has invested his life’s work into building a furniture-buying office. This I did, in tandem with my personal opinion that if an importer is going to bring new product ranges to market, and import multiple containers per month, they want to ensure that the product, assembly, packing, instructions, carton marks, and quality are all always spot-on. They cannot do this at any scale without an on-the-ground presence in China, working on the setting process to ensure that happens like clockwork every time!

So, based on my observations throughout several years, I have drawn up what I see as a very typical scenario across all of the tasks & skillsets required to import furniture from China successfully.

As of 2025, the growing complexity of global compliance, sustainability requirements, and logistics costs has made local representation in China more valuable than ever. For most medium-to-large importers, working with a professional buying office remains the most effective way to maintain product consistency and cost efficiency.

B) Do You Need an Import Licence to Import Furniture from China?

A common misconception is that businesses and individuals importing furniture from China require a license to do so.

In summary: You do not need a special import licence to import furniture from China into most countries. However, you must hold the correct tax or customs identification — such as a VAT or EORI number in the UK, a Customs Bond in the US, or a Fumigation Certificate for wooden furniture imported into Australia.

Generally, this is not true. In this section, we will take a concise look at importing furniture into the UK, USA, and Australia and take a quick look at what is required.

Generally, for most countries, here is the process:

When your consignment (shipment) of furniture arrives – assuming your furniture is coming via sea freight, – you will need to arrange customs clearance and delivery. Typically, this is handled by a freight forward company that you must have pre-selected (either by yourself or your furniture-buying office).

You will need to ensure all the commercial invoice, packing list, bill of lading, and any other required documentation is correct. Remember, if any information is liable, it’s your responsibility that these declarations are all correct – you’re the importer!

You will then need to pay any relevant taxes (VAT, sales tax, duty, etc.), as well as the ocean freight if your buying on an FOB basis, also trucking/haulage port handling, and admin/documentation charges.

These fees should be ‘pre-agreed’ before the shipment sales, otherwise, companies can essentially charge you whatever they want.

Another advantage of working with a furniture-buying office is that when making use of their volume, they will negotiate the best possible logistics charges and exclusively handle this for you.

If you’re importing a full container load of furniture, then typically, when the container is delivered, it’s your responsibility to get it offloaded.

Importing furniture from China to the UK

If you’re importing furniture to the UK, then you necessarily do not need an import license. The basic requirement to import furniture into the country is to either have a VAT number or if you’re an individual or a small business, an EORI number.

No permit or import license is needed as such.

Importing furniture from China to the USA

If you are importing furniture into the USA, you will require a customs bond.

Importing furniture from China to Australia

When importing furniture into Australia, should wood be used in either the product or the packaging, then you need to ensure that the container and furniture are fumigated in China. Also, you must have a fumigation certificate, which is recognized by the Australian border security.

Across the UK, US, and Australia, no specific licence is needed for most furniture categories — only standard tax or customs identification (VAT / EORI, Customs Bond, or Fumigation Certificate).

.

C) What Types of Furniture Are Manufactured in China?

China manufactures virtually every category of furniture — from mass-market flat-pack designs to high-end solid wood collections. Its factories produce for all major segments, including indoor, outdoor, office, and hospitality furniture, making it the world’s most versatile manufacturing base for furniture importers.

When it comes to the types of furniture in China, there is really not much furniture that China doesn’t manufacture! See the below list for the different kinds of furniture that China does:

China manufactures virtually every furniture category, from flat-pack MDF cabinets to luxury upholstered sets.

Indoor Furniture / Upholstered

- Children furniture

- Children bunk bed

- Adult metal bed

- Adult upholstery bed

- Adult wooden bed

- Office chair

- Dining chair

- Leisure chair/stool

- Table

- Painting MDF / PB cabinets / chest

- Paper foil MDF / PB cabinet / chest

- Solid wood cabinet/chest

- Mirror cabinet/chest

- Sofa

Outdoor furniture

- Outdoor rattan furniture

- Outdoor metal furniture

- Outdoor parasol

- Outdoor gazebo

In 2025, the largest export categories from China include upholstered furniture, dining sets, MDF-based cabinets, and outdoor rattan collections. This diversity allows importers to source complete product ranges from a single country while maintaining cost efficiency and consistent quality.

D) Where Are the Main Furniture Manufacturing Regions in China?

China’s furniture industry is divided into four key regional hubs, each specialising in different materials, price points, and product types.

One thing that’s very important when importing furniture from China is to understand the regions of China, and what furniture they produce. Knowing the regions according to their strength of production and their respective extent of qualities helps a great deal in ensuring that you eventually fsource and work with a legitimate furniture manufacture.

It’s always important to remember that while China is one country, it is one huge country with extremism in diversity. Undoubtedly, China has some of the best furniture manufactures in the world. However, in the same vein, China also has some of the worst furniture manufactures in the world, including everything in between!

China’s furniture industry is divided into four major production zones, each with its own specialisation, price range, and level of export experience. Understanding which region produces which type of furniture helps importers identify the right suppliers faster and avoid mismatches in quality or production capability.

- The Pearl River delta (south of China)

- The Yangtze river delta (the central coastal area of China, including Shanghai)

- The western triangle (central China)

- The Bohai sea region (the north coastal area, including Beijing).

The Pearl River delta (south of China)

The Pearl River delta includes provinces such as Guangdong, Fujian. Cities such as Shenzhen, Guangzhou. It is the region where Den Shao Ping, in 1993, famously declared ‘to be rich & glorious,’ and where the first free trade zones were set up. Boarding Hong Kong, it was the natural place for manufacturers’ location. As such, this is a very mature region that’s had a long experience of manufacturing & exporting for foreign furniture brands.

In short, when it comes to importing furniture from China, the Pearl River Delta region is known as top quality, although also more expensive. The types of furniture you can get from this region are vast. Yet certain cities in this region are ceremonious with certain types of furniture.

For example, Dongguan is famous for manufacturing sofas. Foshan is renowned for dining furniture, flat-packed furniture, and all sorts of ‘general furniture’; there is also a road in Foshan which is home to 10km of furniture markets, where furniture factories and brands display their furniture.

Yangtze river delta (the central coastal area of China, including Shanghai)

This region covers Shanghai, and provinces to the north and south, including Zhejiang and Jiangsu. This region manufactures a wide range of furniture and featuring excellent and established furniture manufacturers; it also has some less experienced manufacturers and lower quality.

This region in recent years has also become more expensive, as such is not home to the lowest quality furniture but could be an excellent region for anything from rattan furniture, painted solid wood, metal furniture and more.

The western triangle (central China)

This region of China covers a triangle from Fujian, on the East coast, then inland, including provinces such as Anhui, Shandong, and Henan. In the world of furniture importers, this region is generally a lower-cost region.

In the coastal region of Fujian, you can typically find several painted and flat-packed furniture. Moving inland, you can also find outdoor rattan garden furniture, fabric, and metal beds being typical.

The Bohai sea region (the north coastal area, including Beijing)

This region of China is better known for its large industrial production. However, it’s also the home of glass manufacturing in China. It’s a low-cost region. Typically, you will find glass and metal furniture, such as dining tables. Because of that, supply chains such as dining chairs/upholstery can also be found there.

It’s important to note that the furniture industry in the north, as far as the ‘export market’ goes, is less developed. This translates that if you’re importing any upholstered product, fabric chairs, and sofas, it’s unlikely to encounter the need to source a supplier who can meet fire retardant standards.

Understanding China’s manufacturing regions is the foundation of any successful sourcing strategy. Once you know where specific furniture types are produced and what quality levels to expect, the next step is to plan your import process — from finding and auditing suppliers to managing pricing, logistics, and quality control. The following section outlines this process step by step.

3. A Step-by-step Guide to Import Furniture from China (Global Guide)

Importing furniture from China involves multiple stages — from selecting a reliable manufacturer to ensuring product compliance, negotiating pricing, and managing logistics. Each step requires attention to detail to minimise risk and protect your investment.

In this section, we will be taking you through the step-by-step procedures to import furniture from China!

A) How to Find Reliable Furniture Manufacturers in China

So, the first thing you will need to do is find a factory/chinese supplier. You must remember that finding the right factory is vital! If you find the right factory, you can get reasonable prices, good quality, excellent lead-times, good co-operation, and ultimately a good outcome!

Find the wrong factory, and while you may get super low prices, you may also get high defect rates, bad quality, reoccurring delays, which can quite frankly cost you time, money, and you’ll wish you never bothered!

So, how to truly find the right factory should be the first question.

The first stop for most importers is often Alibaba.com. There are literally thousands of suppliers out there. It’s certainly a perfect starting point for any importer to see what’s out there. However, when it comes to selecting the right supplier, negotiating the right deal one way or another, this is a time-consuming manual job that can’t be conveniently done by a computer algorithm. It’s also a job that requires experience and a specific set of skills to ‘lead you to the gold’ and lines up the right manufacturing companies for the right product.

It’s for this reason that many furniture importers and brands make use of a buying office to utilize their experience, and on the ground presence, to select the right supplier.

Easy Imex staff doing quality assurance on Chinese supplier’s factory

Dealing with a Chinese buying office can often invite factories to quote, who may not be on Alibaba. They are also likely to attend all of the furniture shows in China, where is the only place you will find certain manufactures. For example, some manufacturers may not advertise at all on www.alibaba.com, but instead, every year attend a different trade show. This year, they may be attending CIFF (China International Furniture Fair), the next year they may exhibit at SPOGA (A large outdoor furniture fair held in Germany). As such, if you’re only looking online, there is often a world of furniture manufacture, usually great ones, which you cannot find on sites such as Alibaba.com or globalsources.com

Before deciding on the best Chinese furniture factory, it’s essential not to put all of your eggs in one basket just yet. After selecting several factories, the next step will be to audit them. Auditing these factories will help you to discover who they are, what they are capable of, their overall truth, what equipment and process they have in place, what ethical and sustainability standards do they adhere to, etc.

Again, it’s for this reason that many furniture importers and brands allow buying offices to handle these works, as factory audits are a crucial part of the process that you can’t afford to miss. This is often best left to ‘the team on the ground in China.’

Once a certain number of qualified suppliers (minimum 3) have been confirmed, the next step is to send out an official Request for Quotation.

It’s essential when dealing with a professional manufacturer that you, the buyer, acts as a professional buyer and puts your business out to tender. Again, this is another part of the process the buying office handles for you. A professional IT system that documents product specifications, qualified suppliers, sending out official Request for quotes with set timeframes for manufactures to bid on is best practice.

If you don’t do this, manufacturers won’t potentially treat you as a serious entity and might be opportunistic with quotes. However, some chinese factories may not even quote at all, or better still, they might send a short, unofficial non-binding quote over a text messenger as ‘just a unit price’ with no specification and terms to go with it.

This can become unclear, hard to process and manage, especially the returning data. This may also result in a case of potential waste of time and ultimately could lead to selecting the wrong supplier, as all quotes could mean different things. The suppliers might have interpreted what they are quoting for in the wrong way!

Summary: Many high-quality Chinese furniture factories do not advertise on Alibaba or global marketplaces, but instead exhibit at trade fairs such as the China International Furniture Fair (CIFF) in Guangzhou or the Canton Fair in Foshan. Visiting or working through an experienced buying office ensures you reach legitimate factories rather than intermediaries.

B) Calculate import cost

When you are importing from China, you shouldn’t just know the ‘China cost’ of your furniture, but also the cost of the furniture landing in your country, delivered, and sitting in your warehouse.

Table: Typical Cost Breakdown When Importing Furniture from China

Cost Component | Typical Share of Total | Notes |

Factory Price (FOB) | 40–60% | Depends on material, design complexity |

Freight & Insurance | 15–25% | Varies by route and season |

Import Duties & VAT/GST | 5–25% | Country-specific (UK, US, AU) |

Inland Logistics | 5–10% | Warehouse delivery & handling |

Other Fees | 2–5% | Documentation, port admin, customs brokerage |

In order to do this, all costs to import need to be accounted for. As such, the first step is to ensure that all suppliers from China provide you with similar quotations. ‘FOB’ is standard.

FOB stands for ‘Free On Board,’ and essentially means that the cost quotes include all the charges, not just for the furniture only, but also to export the goods and get them onboard the vessel at the local port in China.

From there, you will need to know the freight and local charges you will be charged. This includes the Ocean freight, local port and handling charges in your country, plus the trucking/delivery charges from the port, to your warehouse. These charges will vary as Ocean Freight changes monthly.

As an importer, you should get these charges either from your China buying-office or your appointed freight forward company. Often, a pleasant buying office will have pre-agreed rates with shipping lines and freight companies utilizing the bargaining power of the total volume of exports they do, to offer the lowest possible prices to their furniture importers.

In 2025, freight costs have stabilised compared to 2021 highs, but remain sensitive to global shipping capacity. Importers should confirm all charges monthly before shipment to avoid unexpected surcharges.

C) Price negotiation

Price negotiation, this is the point that can make or break all the work that you have done so far! However, if you have followed the above steps until now, then at this point the price negotiation should be more of a ‘fine-tuning’ exercise for you.

The reason being, you are now negotiating with qualified factories. There is no point in negotiating the most amazing price even if that’s from a furniture manufacturer that simply cannot meet your quality standards or capacity!

If you have used a buying office, at this point, they definitely must have had multiple qualified suppliers quote on precisely the same specification. As such, there will be a range of prices to view. This will do an exciting reading, and you will be able to rule out any ‘crazy prices.’ Also, you will be able to see what seems to be a ‘reasonable’ cost and, of course, who is the cheapest.

From there, based on other factors, you can select just one or two manufactures to negotiate with seriously.

When negotiating with Chinese factories, focus on long-term cooperation rather than one-time pricing. Factories prioritise steady volume and consistent reorders. Establishing a predictable schedule often leads to better prices and priority production slots over time.

Often, negotiating a better price from this point lies in the hands of the factory’s salespeople. It’s at this point that a face to face meeting with either the owner of that factory or the most senior sales manager suffices as that’s the only way to get a lower price. As such, again, this is a task often best handled by the buying office who will travel to the factory to conduct this face-to-face meeting.

Once at the factory, it’s much easier to discuss everything, to go into detail about elements that can influence the price.

If you have significant volume, instead of a simple discount off the unit price from a container, the factory may agree after the first three orders; from that point, that they will offer you a 5% discount. After all, Chinese factories want volume and continuity of orders. If you can give them what they want, then you have a powerful position to get what you want!

In 2025, most furniture suppliers are open to small initial trial orders if a clear plan for future container shipments is communicated upfront.

What Is the Minimum Order Quantity (MOQ) When Buying Furniture from China?

One of the most common questions from new importers is what the MOQ (Minimum Order Quantity) is when buying furniture from China. This depends on whether you buy factory direct or through a wholesale market.

Minimum order quantities will vary from one furniture supplier to the next. In this section, we will point out the various ways that you can procure furniture in China, and outline what typical minimum Order Quantities you can expect.

Buying Factory Direct

If you’re buying mass-produced furniture from a typical Chinese furniture manufacturer, then you can expect the minimum order to be a container load. Often a 20ft container.

Generally, furniture is bulky. Factories are geared for mass production, and manufacturers need to buy minimum quantities of raw materials and components legs, feet, handles, etc. For all these reasons, and more, are why, generally, Chinese factories will require a customer to order a full container load.

However, the next question is how many different furniture SKU’s or furniture items/ranges can be put into this container? Again, this will vary from factory to factory. Still, typically ordering one container load from one factory, it’s quite normal for them to be able to provide between 2 – 5 different items to fill your container. It’s worth pointing out that this is a point of negotiation, and often factories that are keen to begin co-operating with you will bend their standard minimum order quantities for you on initial orders.

Buying from Furniture Wholesale Markets

Across China, there are various wholesale furniture markets. The key furniture markets are located in Foshan, Guangzhou, Shanghai, Beijing, and Tianjin.

These markets vary. Some of them are there to service the ‘International export market.’ Others are designed for the Chinese domestic market. At the more International Furniture markets, you will find everything from leading Italian furniture brands to small Chinese local furniture manufactures. Generally, in all cases, the minimum order can be as low as one of each item!

However, if you want to buy various pieces of furniture to ship, you will need a buying office or agent to co-ordinate payments, consolidation and packaging of stock for export, and all the export documentation.

If you want to buy these sorts of minimum quantities from wholesale furniture markets, then the only way to do this is to contact a furniture buying office, such as www.easyimex.com, and arrange a buying trip to China.

Table: Typical Minimum Order Quantities (MOQ) by Purchasing Method

Purchasing Method | Typical MOQ | Notes |

Factory Direct | 1 x 20ft container (2–5 SKUs) | Best for stable, repeat orders |

Wholesale Market | 1–2 pieces per item | Ideal for variety but higher per-unit costs |

Via Buying Office | Flexible, depends on combined shipment | Allows consolidation for smaller importers |

D) Sample development and quality assurance

Before giving your factory an order to mass-produce your furniture, it’s vital that you do Quality Assurance! In short, this means checking the sample and signing it off.

The sampling stage is critical for confirming materials, finishes, and assembly accuracy. It is also your only chance to identify design flaws before mass production. Every approved sample should be signed off, photographed, and documented to prevent miscommunication later.

Quality Assurance should cover all aspects of the furniture, the product itself, how it assembles (if an assembly is required), the instructions, and the packaging (especially crucial for e-commerce furniture sellers).

There can be a few things going wrong with the furniture. All issues and mistakes must be ironed out on an agreed sample between the buyer and manufacturer. If this is not done, these mistakes will be mass-produced and become a massive problem for any furniture importer!

To give you an idea, here are a few issues picked up on one product by the Easy Imex Quality Assurance team. All of these issues ONLY became apparent when doing professional Furniture Quality Assurance.

Ex: Quality Assurance on a Computer Desk

To give you an idea, here are a few issues picked up on one product by the Easy Imex Quality Assurance team. All of these issues ONLY became apparent when doing professional Furniture Quality Assurance.

- A white, flat-packed computer desk in white. The material used is a cheap ‘paper’ finish, which means dirty marks cannot be easily removed. If the end customer were to put a dirty cup of coffee on this ‘new’ desk, they would soon be a depressed customer.

- The draws on the computer desk have been made slightly too small; it’s only apparent when checking the physical sample that you cannot entirely lay down a piece of A4 paper flat.

- The cam locks that hold the structure together have been placed on the outside of the panel. This does not give a ‘clean look’ – the structure can be altered, so on the finished product, these are invisible to the naked eye.

- The instructions for the desk are too simple, technical drawings not detailed enough, and ultimately very hard to read.

- The packaging means it’s effortless for the desktop to get damaged while it’s being handled, the packaging needs re-designing.

All of these issues were solved in the second sample. The second sample was then officially signed off by the Easy Imex Furniture quality Assurance team, and successful production and sales began on this furniture line.

In 2025, digital sample reviews via high-resolution video or 3D scans are increasingly common for importers unable to visit factories in person.

Due to the combination of the fact that furniture is generally bulky, and the fact that very often in Furniture Quality Assurance the second round of sampling is required, many furniture importers will either use a furniture buying office or send their own Quality Staff to sign off samples at their Chinese furniture supplier.

E) Furniture Import Compliance and Certification Requirements (UK, US, AU)

Compliance requirements vary by destination country, but all importers are responsible for ensuring their furniture meets safety, chemical, and sustainability standards. Failing to do so can result in customs delays, recalls, or brand damage.

Making sure that your product legally complies with the country you are importing to is crucial, including key import markets such as the United Kingdom. Different regions enforce their own standards for fire safety, chemical compliance, and labelling, so it’s important to confirm these requirements before production begins.

Generally, there are three areas to get right.

Safety compliance

Depending on your country, there will be various standards around product safety. These are in place to protect the end consumer.

For example, load, stability, structure, dimensions, and so on, can all play a role to ensure a product is fit for purpose. For instance, a bunk bed that cannot withstand a certain load on the top bunk, if it fails, could prove extremely dangerous.

Different materials will also have specific tests, again for safety. For example, the glass will have a test to ensure that tempered glass, when it breaks does not break into large shards of glass, but a certain number of small pieces. As such, if you are importing a glass dining table, there may be one test for the table, and also another test for the glass.

As a furniture importer, it’s your responsibility to ensure that the furniture you are importing from China has been specifically tested.

You cannot do this on goodwill either. As an importer, you need to hold the test certificates and the test reports to prove that your product has been tested, and you have the results to prove it.

Remember, as the furniture importer, this is your responsibility, not the China furniture manufacturer!

Chemical compliance

There are also specific standards related to the chemicals used and given off by the furniture. In Europe, for instance, these are covered by REACH.

For example, glues, paints, and chemicals used in foam must all comply with the relevant standards in your country.

Sustainability

More and more, people and businesses around the world care that what they are buying is ultimately coming from a sustainable source. The FSC certifies that the wood used is furniture is coming from a sustainable source.

Summary:

- Safety: Load-bearing, structural, and fire-retardant standards

- Chemical: VOC, lead, and formaldehyde limits (REACH, CPSIA)

- Sustainability: FSC-certified wood and traceable materials

Easy Imex regularly audits factories for compliance with international standards and can arrange third-party testing before shipment if required.

F) Purchasing

Once pricing and samples are confirmed, the next step is to secure a formal purchase agreement that clearly defines all terms, specifications, and quality expectations.

When purchasing a product from China, there is a right way and a wrong way! The first significant thing to get right is to ensure there is a purchase contract in place. The purchase contract should contain the following:

- Clear payment terms

- Furniture specification including product, packaging, instructions

- Amounts

- Agreed tolerances

- Agreed quality standards (most China furniture importers will follow AQL standards).

- Late fines.

While all of these details may have been discussed at some point in time, it’s essential that for each furniture import from China, an explicit purchase agreement is in place.

A written contract signed and stamped by both parties is enforceable under Chinese commercial law and helps resolve disputes more efficiently.

If you are using a buying office, creating and managing the contract is a standard role that they would do for you.

G) Payment options

Payment options can vary under different circumstances and can be negotiated. Generally, most companies that import furniture from China will work along the lines of the importer paying a deposit, then pay the balance against the bill of lading (after the goods have been shipped from China).

Here are a few examples of payment terms, listed from ‘worse case’ to ‘best case.’

100% payment before production even begins

Super high risk as the furniture importer has no leverage against a China furniture manufacturer after they have paid. Typically, the only time this payment term would be applicable would be if a furniture order is minimal, say less than USD 5000.

30% deposit then 70% before shipment

Here, the importer pays a deposit on the order, then the manufacturer produces the furniture, and later before the goods are shipped, the importer must pay the remaining 70% balance. This is not ideal from a risk or cash-flow perspective of the furniture importer. If the furniture manufacturer were requesting these payment terms for any order above USD 10,000, it should ring an alarm bell as to why they’re offering such poor conditions.

30% down, 70% against bill of lading

These are STANDARD terms any furniture importer should get from any a China furniture manufacturer or China furniture-buying office. Simply, it means that the importer pays a deposit and is able to control the quality and standard of the goods. The goods are then shipped out of China, and the importer can pay the balance against the bill of lading when they know that their furniture is in a container, and on the way to them. It also helps importers manage their cashflow a lot better.

0% deposit, 100% against bill of lading

These are good payment terms where the China furniture manufacturer will agree to manufacture based on a firm’s purchase order and contract. They will then ship the goods out of China, leaving the furniture importer to pay only after his or her goods have been shipped. Generally, these payment terms will only be achieved if you’re using a China furniture buying office, such as Easy Imex.

0% deposit 100% balance after 90 days (importing goods on credit)

These are pretty much the best payment terms possible for importing furniture from China. Basically, the only way these terms can be achieved is by making use of a dedicated furniture buying office such as Easy Imex. Getting credit terms will require meeting specific criteria, such as trading history, credit checks, and contracts.

Table: Common Payment Terms for Furniture Imports from China

Term | Description | Risk Level | Common Use |

100% Prepayment | Payment before production | Very high | Small, urgent orders |

30/70 Before Shipment | Deposit + full balance pre-shipment | Moderate | Common for new importers |

30/70 Against B/L | Deposit + balance after goods shipped | Low | Standard industry practice |

0% Deposit, 100% Against B/L | Payment after shipment | Very low | For trusted buyers with history |

0% Deposit, 90 Days Credit | Post-shipment credit | Minimal | Large or long-term clients via buying office |

In 2025, credit terms are available mainly through buying offices or long-standing supplier relationships that can verify trading history and financial stability.

H) How to Ensure Furniture Quality When Importing from China

Quality Control is the most basic function that should be carried out on all Chinese furniture purchases. Chinese furniture manufacturers, both big and small, all have some degree of quality issues during production from time to time. Depending on the factory, these could vary a lot.

Quality control is not a one-time activity but an ongoing process that should begin before production and continue until container loading. Every stage offers an opportunity to prevent defects rather than fix them later.

It’s worth pointing out that as vital as quality control is, no amount of quality control will ultimately turn a bad Chinese furniture manufacturer into a good one!

Adam Gilbourne drop testing flat packed furniture in a Chinese supplier factory.

The critical point is that as a furniture importer, whether you are importing one container load of furniture either as a one-off or as a regular furniture importer, if a quality issue is missed on any batch, the effects on your furniture business can be severe.

The reason being, once you have imported your goods, they cannot be returned to China. You (the furniture importer) now has the stock, and you’re left to either sell it as a second-hand item, fix the issues/mistakes, or apply some damage control means. You can sort out the highly defective furniture from the stock that is sellable, or worst of all, dispose of the stock as it either cannot be sold, or a commercial decision has been made that selling below par is damaging to your furniture brand!

As such, each furniture import must be quality checked! Various forms of quality control can be carried out; in short, these are:

- Mid production inspection – checking production halfway through to ensure the right materials/colors, etc., are being used.

- Pre-shipment inspection – this is an inspection of the batch at the end of production.

- Container load check – to ensure that the right quantity of furniture is loaded as well as making sure the container is loaded correctly, with a case. This is especially crucial with something such as a glass mirrored furniture.

- Online inspection – this is a situation whereby a Quality Inspector visits the factory every day during the entire production process.

The simple rule is, the more quality control you do, the more you reduce your risk! However, it’s essential to find a practical balance between cost and the amount of quality control you practice.

If you’re working with a furniture buying office, such as Easy Imex, then they will have a Furniture Quality Team in place. Their Furniture Quality Team will assess each furniture manufacturer, each furniture SKU (item), and put the right quality control plan in place for your furniture.

This can vary, anyways. Also, the Furniture Quality team will help you to design, manage, and implement this plan. For instance, when dealing with a new Chinese furniture manufacturer, on the first order of a complex piece of furniture, the types and levels of inspection will be much higher compared to a manufacturer that is a well-known supplier. And also, it has made the same piece of furniture for multiple containers each month for the past two years.

“Good” Furniture Quality Control

There are several ‘quality control’ companies that carry out inspections. A good quality control inspection will report all findings, including the specifications of the product, assembly, instructions, packaging, minor and major defects accurately.

Any good furniture quality control report will be marked either as a ‘pass’ or ‘fail’. However, the importer should study this report and fully understand and then make their judgment.

For example, what a third-party furniture quality inspector may think is a ‘minor’ defect, you, the furniture importer and brand, may feel that these minor defects are, in fact, significant defects and not acceptable.

It’s for this reason that many Chinese furniture importers use a buying office, as there is a greater understanding of what the furniture brand’s quality expectations are.

After a quality control report is done, it’s not yet ‘job over’ at this point, still. The next actions need to be decided. For example, if the quality issues are not acceptable, does the batch need to be re-worked then re-inspected? Can the furniture be shipped, and should either spares or compensation be agreed before shipping? Is it decided that the furniture can be shipped and instructions then need to be given to the freight forward office or shipping line?

“Bad” Furniture Quality Control

There are various forms of ‘bad quality control’ that China furniture importers can experience.

First, when making use of a third-party company, the actual inspector carrying out the inspection and report can be very much ‘detached’ from the needs of the furniture importer. As such, a ‘GIGO’ (garbage in garbage out) effect can be found. Meaning, the actual inspector is not familiar with what the furniture brand deems acceptable or unacceptable!

Not only that, but a third-party furniture quality control can be quite emotionally detached from the furniture importer they are ultimately working for. Maybe they will never do any inspection for this brand again? One genuine risk for businesses that import furniture from China is that the Quality Control Inspector is either lazy, corrupt, or both!

When the inspector is at the factory, maybe the factory is fully aware that there are quality issues; however, they do not wish for these to be reported to the furniture importer. As such, they do anything they can to either bribe or influence the inspector. Many Chinese manufacturers have reported that they have been asked, ‘how much will it cost you if I fail this batch?’ before!

It’s for this reason that furniture importers prefer to use a professional buying office that has full-time Quality Control inspectors who are fully accountable and that there is continuity over the same inspectors carrying out quality control for the same furniture importer.

Furniture Quality Management

A furniture buying office will have a professional quality management system in place that ensures:

- The right level of Quality Control on your furniture

- Agreed standards of working are observed

- Full-time inspectors and accountability over results

- Interpreting the Quality Control results, and then taking the right actions for either re-working and reinspection or shipping out.

Today, most professional buying offices integrate digital inspection reports, photo checklists, and live video audits into their QC process, giving importers real-time visibility of production quality.

I) Furniture Shipping from China: Transit Times and Container Sizes

When you ship furniture, the ideal way to ship these is ‘by the container load.’ See table below of standard shipping containers, and the amount of cubic meter volume they hold.

Table: Container Sizes for Furniture Shipping from China

| Container Size | Cubic Meter Volume | Dimensions |

|---|---|---|

| 20ft | 28 CBM | 5898mm (L) x 2352mm (W) x 2393mm (H) 20’GP |

| 40ft (standard) | 58 CBM | 12032mm (L) x 2352mm (W) x 2393mm (H) 40’GP |

| 40ft HQ | 68 CBM | 12032mm (L) x 2352mm (W) x 2698mm (H) 40’HC |

When your shipping importing furniture, unless your shipping by airfreight (much more expensive and likely not commercially viable to import furniture!), your furniture will be loaded into a container.

Sea freight is the most cost-effective method for furniture importers, although it requires proper scheduling and documentation. Many Easy Imex clients in the United Kingdom import through major ports such as Felixstowe, Southampton, and London Gateway, which handle some of the highest container volumes arriving from China into the UK.

You can either import a ‘Full container load’ known as FCL or a ‘Less than a Container Load’ known as ‘LCL.’

Table: Container Types, Capacity and Typical Use for Furniture Shipment

Container Type | CBM Capacity | Typical Use |

20ft | 28 CBM | Small orders or trial shipments |

40ft Standard | 58 CBM | Mid-volume shipments |

40ft High Cube | 68 CBM | Large-volume or bulky furniture |

LCL (less than a container load) shipments

If you have a small order or even a sample order, LCL shipments may be the only option. However, your goods will have to travel from the Chinese furniture manufacturer to the port, loaded into a ‘shared container’ When goods arrive in your country, they will need to be unpacked at the port so your consignment of products can be delivered to you. In reality, this means that your furniture is handled by an awful lot of people who do not necessarily handle your goods at all times with much care.

As a result, LCL shipments are notorious for arriving damaged. So, if you are going to ship in this way, it’s highly important to ensure that your furniture manufacturer has packaged the furniture exceptionally well.

FCL (full container loads) shipments.

When you order a full container load from a furniture manufacturer, this means that the container will be delivered to the factory, and the factory will then load the goods into the container.

A seal is then put on the container once it’s all loaded and doors closed. The seal will not be opened until the container arrives, and the furniture importer opens the container. This means that between the furniture manufacturer and the importer, no one else has handled the goods!

As long as the container has been loaded correctly, and with care, the chance of damage when the goods arrive with the furniture importer is very little.

At Easy Imex, we offer and recommend Container Loading Inspections for all furniture importers. This ensures:

- That the correct quantity is loaded/recorded

- That as the container is being loaded, the laborers loading the container do so with utmost care.

- That cartons are stacked the right way, making sure that as they load furniture to the top part of the container, they are not treading on other units of furniture to do so and potentially damaging furniture by treading on boxes at the bottom of the container.

Which size of furniture container is preferable?

Generally, no matter what country you are in, you should always use standard size containers, 20ft, 40ft, 40ft HQ as per the table above.

The bigger the container, the lower the cost ‘per cubic meter’, meaning your ultimate landed price on the furniture will be cheapest by using a 40ft container.

The reason being is that most ports around the world charge the same or very similar amount of money to handle a 20ft as a 40ft container.

In a 40ft HQ container vs. a 20ft container, while the cubic meter volume is more than double, ocean freight is less than double.

You also have a trucking/haulage cost; basically, this is a similar charge for a 40ft HQ container as a 40ft container. This again signifies more value and an overall lower cost per cubic meter by importing in a 40ft HQ container.

Most importers will use a combination of their furniture procurement office and a forward freight company to handle the logistics/shipment of your furniture.

The furniture procurement office will handle everything out of China; they will then provide both you, the furniture importer, and your freight forward company in your country with all relevant documentation to import. Bill of lading, commercial invoice, packing list, etc.

When the container arrives at your local port, the freight forwarder will then confirm and arrange both the customs clearance and co-ordinate delivery with the furniture importer.

For importers in Australia, Easy Imex regularly manages shipments through Sydney and Melbourne, coordinating with local freight forwarders to ensure smooth customs clearance and inland delivery.

One final note to any new furniture importer is that while importing furniture, the import-export process may seem daunting. Typically, this is quite an easy part of the process.

Typical lead times for furniture imports range from 45–90 days, depending on order complexity and shipping route. Importers should plan for production time, freight schedules, and customs clearance when calculating delivery dates.

One final note to any new furniture importer is that while importing furniture, the import-export process may seem daunting. Typically, this is quite an easy part of the process.

4. Common Challenges When Importing Furniture from China

Even with China’s mature and reliable manufacturing base, importing furniture is not without its challenges. Many issues that importers face are not caused by bad luck, but by a lack of preparation, quality management, or cultural understanding. Below are the most common challenges, based on more than two decades of Easy Imex’s experience working with global furniture importers.

Inconsistent Quality Control

One of the most frequent problems faced by importers is inconsistency between production batches. A supplier may deliver excellent samples but struggle to maintain the same standards during mass production.

This happens for several reasons: different workers or subcontractors handling production, variation in raw material batches, or inadequate in-line inspection.

To prevent this, implement a strict quality control plan that includes pre-production approval, mid-production checks, and pre-shipment inspections. If you are not based in China, using a professional buying office or third-party QC company is essential to verify quality at each stage.

Communication Barriers and Cultural Misunderstandings

While many Chinese factories employ English-speaking staff, communication gaps remain a common source of costly mistakes. Direct translations can miss nuance, leading to incorrect specifications or packaging details.

Furthermore, cultural differences can affect how problems are reported — suppliers may avoid delivering “bad news” quickly, delaying corrective actions.

Working with bilingual project managers or a local buying office bridges this gap, ensuring that specifications, materials, and deadlines are clearly understood and documented in Chinese.

Unverified or Misleading Suppliers

With thousands of furniture suppliers in China, it is easy for inexperienced importers to mistake a trading company for a factory. While not all traders are problematic, some add unnecessary mark-ups or exaggerate their production capacity.

Always verify whether you are dealing directly with a manufacturer by requesting their business licence, factory address, and on-site photos or audit reports. Importers should also check whether the factory holds relevant certifications, such as ISO, FSC, or BSCI, depending on the product type.

Freight Volatility and Rising Logistics Costs

Shipping costs have stabilised since their 2021 peak but continue to fluctuate with fuel prices and container availability. Importers who fail to lock in freight rates early in the production process may face sudden price increases that erode profit margins.

Building a long-term relationship with a logistics provider or working through a buying office that manages freight contracts can help secure consistent rates and reliable shipping schedules.

Compliance and Certification Gaps

Every importing country has its own set of product regulations. Failing to meet these standards can lead to customs holds, product recalls, or reputational damage.

For example, the UK and EU require fire-retardant foam and fabric certification, while the US may demand labelling under the California Technical Bulletin (TB117). Australia enforces fumigation certificates for wooden furniture to prevent pest infestation.

Importers should never assume a factory automatically understands destination market standards — compliance should be confirmed and documented before production begins.

Over-Reliance on a Single Supplier

Many importers, particularly those new to the industry, rely heavily on one “trusted” factory. While this may seem efficient, it exposes the business to major risk if that supplier encounters delays, pricing changes, or quality issues.

Diversifying your supply base across at least two factories — ideally in different regions — provides flexibility and negotiating power. It also ensures continuity if one production line experiences disruption.

Hidden Costs and Documentation Errors

Smaller importers often overlook additional expenses such as port charges, insurance, customs brokerage, and inland delivery fees. These “last mile” costs can significantly impact profit margins.

Equally common are documentation errors — for example, mismatched invoice details, incomplete packing lists, or missing certificates — which can delay customs clearance.

Establishing a pre-shipment documentation checklist and having all documents reviewed by an experienced freight forwarder can help avoid unnecessary delays and penalties.

Summary

Importing furniture from China can be highly profitable when managed correctly, but it requires rigorous systems and reliable local support. The difference between a successful importer and a struggling one often comes down to attention to detail, quality management, and on-the-ground oversight.

For most importers — particularly those scaling up — partnering with a professional buying office like Easy Imex provides a practical way to navigate these challenges efficiently while maintaining profitability and brand reputation.

5. Why Work with a Furniture Sourcing Agency in China (and How Easy Imex Helps)

Importing furniture from China can be complex — finding reliable suppliers, maintaining quality, and managing logistics all require on-the-ground support. Easy Imex was created to make this process simple, transparent, and dependable.

Experience and Local Expertise

Founded in 2004 by Adam Gilbourne, Easy Imex has worked with thousands of importers across more than 30 countries. With offices and staff in key furniture hubs such as Foshan, Dongguan, Ningbo, and Shanghai, the team provides local oversight, supplier verification, and hands-on project management at every stage.

End-to-End Import Management

Easy Imex handles the full process — from factory sourcing and price negotiation to sample development, quality control, and shipping. Every client is assigned a dedicated project manager who monitors production and ensures that goods are inspected before they leave China.

Quality and Compliance

The company integrates strict inspection checkpoints and supports compliance with FSC, REACH, and UK fire-retardant standards. This ensures products meet destination market requirements and avoids costly customs issues or quality complaints.

Transparent and Scalable

Easy Imex operates on clear service fees, not factory commissions. With access to trusted logistics partners and competitive freight rates, importers can scale confidently — whether shipping one container or managing ongoing monthly orders.

Supporting Businesses of All Sizes

From first-time importers to established retailers, Easy Imex helps clients of all scales source efficiently, maintain quality, and grow sustainably.

Planning to Import Furniture from China? Contact us!

Take the first step to obtaining the right furniture factory at a reduced price while keeping your quality standards. Fill-in the form below!

Frequently Asked Questions (FAQs)

- How long does it take to import furniture from China?

On average, the full process takes 45 to 90 days, including production, shipping, and customs clearance. Lead times vary depending on order size, materials, and destination country. - Do I need an import licence to buy furniture from China?

In most cases, no special licence is required. Importers just need the appropriate registration for their country — such as a VAT or EORI number in the UK, a Customs Bond in the US, or a Fumigation Certificate for wooden furniture in Australia. - What is the minimum order quantity (MOQ)?

Most furniture factories in China require a 20ft container per order, typically containing 2–5 different products (SKUs). Smaller importers can work through a buying office to consolidate orders. - How can I ensure quality when importing furniture?

Always conduct pre-production, in-line, and pre-shipment inspections. If you cannot visit factories in person, work with a buying office or third-party QC team that can inspect goods on your behalf. - Is importing furniture from China still profitable in 2025?

Yes. Freight rates have stabilised since the pandemic, and China remains the world’s most efficient and competitive furniture manufacturing base.

Excellent tips here! Thank you!

You got a very fantastic website, Gladiola I noticed it through yahoo.

Why is it good business to import furniture from China?

Importing furniture is a good business because of the reduced prices offered by many suppliers in the country. In addition to this, in Europe they have a 0% tax rate, something that increases even more our commercial margin.

Why buy furniture from China and not from other countries?

Buying in China today is a synonym of fair price for what you receive. A large part of the products you buy from non-Chinese companies sell products that they themselves have bought from China, and they sell it to you for a higher price. China is the factory of the world, and that is why more and more companies decide to entrust the manufacturing of their products to China.

¿Which are the advantages of importing furniture from China?

Deciding to invest in furniture is expensive. However, if you decide to buy furniture wholesale, you greatly reduce your expenses. Another plus point is the number of furniture manufacturers in China. There are more than 50.000 and most of the design shops manufacture here, so you can have good prices and different styles that can be adapted to your taste. Another benefit is the Chinese tradition. The way of making is following the traditional means of carpentry, having a longer life.

Main risks when importing furniture from China

The main risks when importing furniture from China are:

Cultural and language barriers, slowness in some parts of the negotiation, changing decisions, regulations or problems with quality standards.

Therefore, at Easy Imex we help you to import furniture, minimising the possible risks.

What kind of furniture can be imported from China?

Any type of furniture can be imported from China, from rattan furniture, painted solid wood, metal furniture and much more. That is why a lot of companies import from China, because of its wide variety and range of products.

Is it still worth it to import furniture from China after the COVID-19 crisis?

Though there is no doubt many businesses importing furniture from China saw a huge initial boom after COVID, many of the same companies are now facing serious challenges.

Furniture importers have no choice but to raise prices to consumers. Currently, freight costs are expected to reduce into 2022, although they are perhaps never expected to return to pre-COVID levels.

Resultantly, many furniture importers and retailers have looked to source furniture away from China. However, it’s worth noting that the freight and raw material price increases are not exclusive to China but are in fact a worldwide issue affecting furniture manufacturers across the globe.

Is it worth finding a different furniture manufacturer other than China?

Chinese furniture importers have seen an increase in their costs and have no choice other than to raise prices to consumers. As a result, many furniture importers have been looking to source furniture from outside China. However, it is important to note that rising freight and raw material costs are not unique to China and are a global problem.

What do I have to consider before importing furniture from China?

The are a couple of things that you have to take into account when importing furniture from China:

Import business model: For any company that wants to import furniture from China, its business model as an importer must be aligned with China’s model. What China does well is mass production. So if this is not your model, don’t consider buying from China.

Furniture import licensing: If you are importing furniture into the UK, you do not necessarily need an import licence. The basic requirement for importing furniture into the country is to have a VAT number or, if you are an individual or small business, an EORI number.

Types of furniture in China: You have to know what kind of furniture you want to import. Almost any type of furniture can be manufactured in China